Solar panels are designed to endure extreme exposure to the elements for at least thirty years. The materials used must withstand ultraviolet radiation, ozone attack, moisture resistance, and impact resistance.

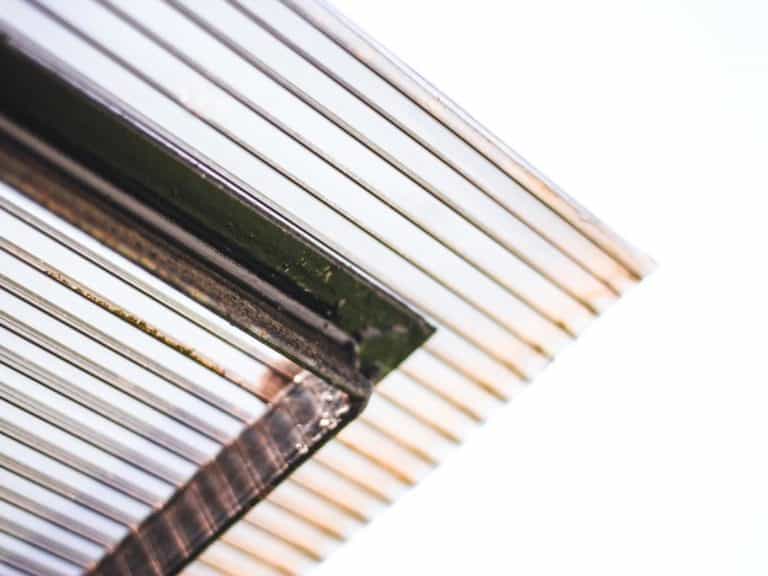

The properties of Plexiglas® make it an ideal substitute for tempered glass in solar panels. Plexiglas® is lighter, impact-resistant, and can be treated to prevent ultraviolet and ozone degradation. Resulting in solar panels that are lighter, cheaper, and more durable than those with tempered glass.

Plexiglas® is the tradename for a solid transparent plastic or polymethyl methacrylate or acrylate. The material was invented before World War II when it was used for the domed cockpit windows of bomber planes.

Acrylate or Plexiglas® has some properties that make it the ideal material for the construction of solar panels:

- Cheaper than glass

- Similar impact resistance to tempered glass

- Lighter than glass

- More scratch-resistant than glass

- Better light transmittance than glass

- A better insulator than glass

- Easier to fabricate and form than glass

- Safer than glass

Tempered glass is still preferred to Plexiglas® in some solar panel applications, but when lightweight solar panels are required, the use of Plexiglas® is quite common and acceptable. Let’s look at when Plexiglas® solar panels make more sense than tempered glass panels.

Plexiglas® Is The Best Synthetic Alternative To Tempered Glass

Plexiglas® is not the only thermoplastic considered an alternative to tempered glass, but it is the best alternative of all.

The airplane engineers also considered Styrene, Polycarbonate, and Polyethylene terephthalate glycol (PETG) for use as transparent cockpit glass. Unfortunately, these substances all became yellow and hazy due to UV exposure.

The benefit of Plexiglas® over tempered glass was that it was almost equal in strength but weighed half as much as glass. This made it an ideal material for airplanes where weight and strength matter.

Tempered Glass Solar Panels Vs. Plexiglas® Solar Panels

The best solution is tempered glass solar panels in large roof-mounted solar array installations. It is unavoidable to have the installers or maintenance technicians walk on the solar panels.

The tempered glass can better distribute the force and not crack or damage. The tempered glass is heat-treated at 600 degrees Celsius and becomes five times stronger than ordinary glass.

Tempered glass was developed as windshields in cars and trucks due to its excellent thermal and mechanical damage resistance. When it breaks, the structure of the tempered glass causes it to fracture into many tiny shards that are less prone to injury than sharp jagged pieces of glass.

Tempered glass soon found applications around the house where human safety was of prime consideration.

For solar arrays mounted on ground-mounts, yachts, vans, RVs, and camper vans, the weight of the solar panels was once again of prime concern. Plexiglas® was an ideal substitute for tempered glass and helped limit weight and cost.

The Plexiglas® also made the solar panels able to be installed on curved surfaces without the risk of cracking. Whenever the weight and strength of the solar array become a primary concern, the Plexiglas® solar panels are used in preference to tempered glass panels.

See also: Solar Panel Protection: Essential Tips and Tricks for Prolonging Lifespan

The Light Transmissibility of Plexiglas® Vs. Tempered Glass

Plexiglas® has light transmissibility of 92% versus 90% of tempered glass, making it the better of the two materials for solar panels.

The most efficient solar panels at present are only 23%, with the bulk of the solar radiation hitting the panel’s surface being lost to thermal radiation or being reflected off the panel’s surface.

The 2% difference in solar transmissibility is significant and can be further enhanced by creating a textured surface that will be less reflective than the smooth surface of tempered glass.

Cooler solar panels perform better than hot solar panels, and Plexiglas® is less prone to cracking at sub-zero temperatures, making them ideal for cold climates. Tempered glass solar panels are less insulating and thus better for hot climates where heat buildup decreases the solar panel efficiency.

Protecting Your Solar Panels Behind Plastic Sheets Or Glass

Solar panels are designed with a robust protective surface layer of tempered glass or Plexiglas® and will not benefit from being covered by additional layers of plastic sheeting.

Solar panel engineers have designed panels to survive the rigors of the elements for as much as thirty years. Placing additional glass or plastic sheeting above the surface of the solar panel will reduce the energy efficiency and may even lead to faster deterioration of the panels.

The risk of trapping thermal energy near the solar panel will cause it to be less efficient. Solar panels perform best at low temperatures as the resistance to electron flow is lower when the kinetic energy of the particles in the solar panel is at a minimum.

Covering the solar panel behind additional sheeting of plastic or glass will trap heat and moisture, leading to the growth of algae on the panel surface. You should be able to gently wash any dust or soot buildup from your solar panels every few months, depending on the level of pollution in your area.

The soot fallout from the giant forest fires will cause a thick layer of buildup on your solar panels that you need to clean off to maintain maximum efficiency of your solar panels.

Plexiglas® solar panels are easy to clean off with a soft-bristled broom and a gentle stream of water. The surface is more scratch-resistant than glass and easier to clean.

Will Additional Plexiglas® Sheets Protect My Solar Panels?

Placing additional Plexiglas® sheeting over your solar panels will provide more protection against hail damage or other impact damage but will severely inhibit the panels’ efficiency.

Solar panels are designed to survive exposure to extreme weather conditions, and placing additional levels of protection over the panels will not be worth the cost and adverse impact on solar energy generation efficiency.

Tempered glass is about five times stronger and more impact resistant than ordinary glass. Plexiglas® is at least as strong as tempered glass and will not need additional layers of protection.

Resources