With the proliferation of solar installations, one of the biggest concerns is the potential effect discarded solar panels could have on the environment. Fortunately, recycling technology also does as the demand for solar power grows.

Solar panels are completely recyclable, and not only is this excellent news for the environment, and it bodes well for consumers and PV suppliers alike. Recycling solar panels add more power to the grid by reducing the additional energy required to manufacture more panels.

For this discussion, we will consider the following key areas :

- How long do solar panels last

- The process of solar panel recycling

- Types of recycling

- Benefits of recycling solar panels

- Recycling in Europe VS the USA

There is much more to recycling solar panels than you think; read on to discover more.

How Long Do Solar Panels Last?

According to manufacturers, solar panels should last around 30 years before decommissioning. The generation loss on solar panels is generally considered approximately 20% over their lifespan.

A loss of 10% in efficiency would occur in the first ten years, with that number reaching 20% when the panels reach 25 years. These stats are the industry standard and agreed on by most reputable manufacturers.

The actual lifespan, however, is somewhat different. Since solar PV has been around since the 1990s, there has been some conclusive data that the efficiency levels decrease less than expected over time.

With good maintenance and improvements in design, solar panel efficiency only drops around 6%-8% over 25 years! This means that the actual lifespan could extend to 40 years or possibly more, but with decreasing efficiency.

How Do You Recycle Solar Panels

Recycling solar panels is tricky, and it requires some specific technology to do it properly, but essentially they are broken down and the various elements removed for recycling.

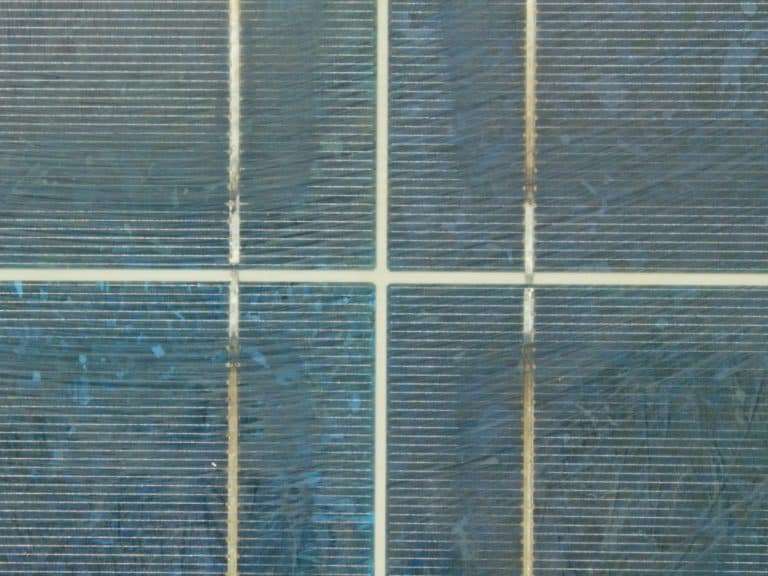

There are two types of solar panels, the silicon-based panel and the thin film panel, and each has a different recycling process.

Because they are made of glass, aluminum, silicon, and other metals, the panels must first be disassembled, and the various materials removed and then processed accordingly.

Because silicon panels are more common, their recycling process can be done using existing industrial technology, while the thin-film panels use a different approach.

The increasing level of research has led to improved recycling technology.

This means recycling solar panels can achieve around 95% effectiveness, and many companies are looking to improve that standard.

See also: Are Solar Panels Recyclable? Uncovering the Truth about Solar Waste Management

What Are The Types Of Solar Panel Recycling

There are a few different recycling processes used depending on the type of panels being recycled:

- Mechanical recycling

- Chemical/thermal recycling

- Refurbishment & reselling

What Is Mechanical Recycling?

Mechanical recycling is where the panel is broken down, and the components are separated before recycling.

As the name implies, the panel is broken down. The materials removed, like the aluminum frame and the glass, silicon, and wiring, can be ground into a mixture known as glass cullet and used for building materials.

However, smaller components like the wiring and silicon can be removed and reused if different technologies are available.

What Is Thermal / Chemical Recycling?

Thermal or chemical recycling uses more advanced methods to remove and recycle components.

This is a more intricate process and utilizes chemistry at the molecular level to extricate the various materials and components for reuse.

With more advanced systems, even the smaller components like the minute silver wires that carry current can be removed and repurposed!

What Is The Refurbishment And Resale Of Solar Panels?

Like second-hand cars, solar panels in reasonable condition can be restored and resold in the market and recycled for use.

While recycling often means the breakdown of panels, there is a market for utilizing refurbished panels for smaller installations where maximum efficiency is not required, such as traffic lights and e-bike charging stations.

While they cannot be used for solar farms as they don’t produce enough power, they can be repurposed in non-essential systems.

How Are Silicon Solar Panels Recycled?

Silicon solar panels go through several processes, from disassembly to thermal treatment through recycling.

Before we look at how solar panels are recycled, we need to understand the other materials used for their components and how they are recycled.

- There are two distinct types of solar panels: silicon and thin film. Each is built slightly differently, with different percentages of materials. Silicon panels are 76% glass , 10% plastic, 8% aluminum, 5% silicon and 1% metals while the thin-film panels are 89% glass, 6% aluminum, 4% plastic and 1% metals.

First, the panels are entirely disassembled to separate the glass and aluminum sections. 95% of the glass is reusable, and the metal parts on the external frame are recycled for re-molding.

The rest of the materials are thermally treated at 500°C or 932°F to release the chemical bonds between the cell elements. Once the plastic capsule has evaporated, the silicon cells can be processed.

After the heat treatment, the green hardware is removed, and 80% of this can be recycled while the balance is refined even further. The silicon wafers are etched away using acid, and broken wafers are used to create new ones.

Around 85% of the silicon is recycled.

How Are Thin-Film Panels Recycled?

By contrast, recycling thin film is a little more violent! The panels are put through an industrial shredder to reduce them to particles of around 4mm-5mm, allowing the laminate that binds the materials to break up.

Unlike their silicon counterparts, the thin-film panels have both liquid and solid components. These are separated using a rotating screw that keeps the solid particles in orbit in a tube, and the liquid drips out and is caught.

The liquid is then purified, and the processed liquid is then subjected to metal processing to separate the various semiconducting materials, and 95% of this is reused.

The interlayer materials contained in the solid matter are of different densities and are separated using a vibrating surface. The result is pure glass, easily used to manufacture new parts.

What Are The Benefits Of Recycling Solar Panels?

As you can see, recycling solar panels is very efficient, which means less and less of this hazardous material is left in landfills. This is only one of the benefits of solar waste recycling.

As the quantity of solar installations grows globally, the number of companies offering to recycle will increase proportionately.

This presents an opportunity for a new industry to grow and create better technology to make this process more efficient and reduce the carbon impact on the planet.

How Solar Panel Recycling Compares In The USA VS Europe

Europe has strict protocols that compel manufacturers to finance the collection and recycling of their products. While the USA is not as vigilant, this is changing, and more states are imposing similar protocols.

Europe started with PV systems earlier, and the requirements for clean energy have driven that industry and the recycling side to far better levels than in the USA.

Washington State has passed a law that will come into effect from 2023 with similar collecting and recycling panels requirements. Still, more states are needed to prevent many of the current solar panels in the USA from ending up in the waste stream rather than in proper recycling plants.

The volume of panels shipped to the US has increased in the past few years, and this is expected to increase further as demand for green energy grows.

Congruently, the need for efficient regulations on recycling and technology must evolve to make this incredibly efficient energy source sustainable.

Resources