The sizing of the cables for solar systems is critical to the performance and safety of the system. Most household fires result from electrical faults that lead to the overheating of conductors, which leads to a fire.

An array of solar panels will capture and convert the sun’s energy to electrical power. The flow of charge in the wires to which the solar panels are connected is limited by the thickness of the copper wire. The most commonly used wire gauge connecting solar panels is 10 AWG.

Why 10-American-Wire-Gauge (AWG) is selected as the standard for external connection of solar arrays due to the following:

- Oversized for safety & voltage drop

- Low resistance for solar current of 30 Amps per single panel

- The voltage drop over distance is low

- Cable is flexible

Consider water flowing through a hosepipe. The bigger the diameter of the hose, the easier the water flows. Short sections of hose flow much easier than longer sections of hose. Let’s look at how we can use the water flowing in a hosepipe analogy to understand the sizing for solar panel cables.

How Does The American Wire Gauge System Work?

The AWG sizing system is based on the number of times the wire is pulled thinner. For example, a Zero Gauge (0 AWG) has a diameter of 0.325 inches (8.25 mm), giving it a cross-sectional area of 53.5 mm2.

After one additional pull through the wire stretching machine, we get One Gauge (1 AWG) wire with a diameter of 0.289 inches (7.35 mm) with a cross-sectional area of 42.4 mm2.

After ten stretching cycles (pulling cycles), we will obtain a Ten Gauge (10 AWG) with a diameter of 0.102 inches (2.59 mm) and a cross-sectional area of 5.26 mm2.

Using the water hose pipe analogy, the 0 AWG wire has ten times the cross-sectional area of the 10 AWG wire and thus will have ten times less resistance to current flow.

The current flow has reduced from 170 Amp for 0 AWG to 40 Amp for 10 AWG copper wire at a temperature of 194°F (90°C). The cross-sectional area has reduced tenfold, and the current-carrying capacity has reduced approximately fourfold.

Table 1: American Wire Gauge Amperage @ 90°C (194°F) for Copper

| American Wire Gauge (AWG) | Diameter (in) | Diameter (mm) | Cross-sectional area (mm2) | Copper Wire@ (Amp) |

| 0 (1/0) | 0.325 | 8.25 | 53.5 | 170 |

| 1 | 0.289 | 7.35 | 42.4 | 145 |

| 2 | 0.258 | 6.54 | 33.6 | 130 |

| 3 | 0.229 | 5.83 | 26.7 | 115 |

| 4 | 0.204 | 5.19 | 21.1 | 95 |

| 6 | 0.162 | 4.11 | 13.3 | 75 |

| 8 | 0.129 | 3.26 | 8.36 | 55 |

| 10 | 0.102 | 2.59 | 5.26 | 40 |

| 12 | 0.0808 | 2.05 | 3.31 | 30 |

| 14 | 0.0641 | 1.63 | 2.08 | 25 |

Amperage tables exist for copper cables reflecting the current carrying capacity of the different gauge cables at different operating temperatures.

Temperatures as high as 150°C are considered when selecting cables for wiring up solar panels. As the wire gauge thinner and the resistance increases (current capacity decreases), wires can overheat and start melting.

Standard Cables For Solar Panels

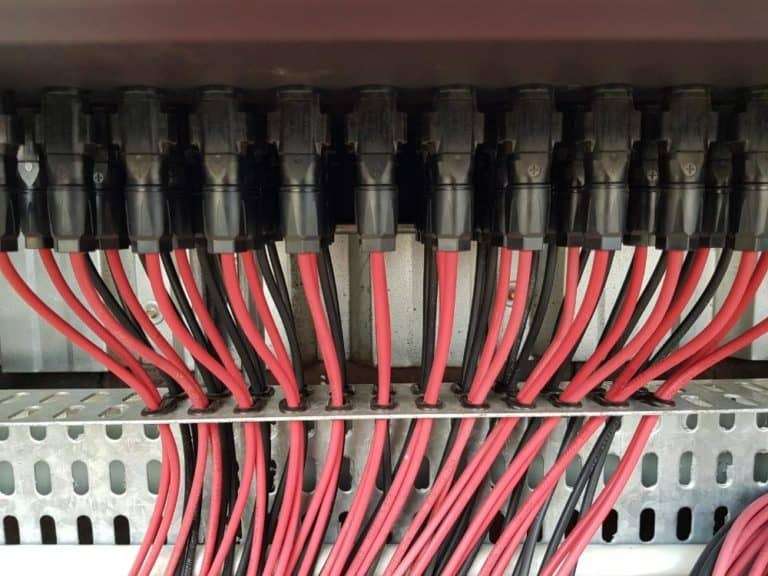

Solar System installers have considered the current loads, distances from charge controllers, voltage drops, and operating temperatures. They have standardized 10 AWG PV-rated wires for connecting solar panel arrays.

The 10 AWG solar cables are widely accepted as containing a sufficient safety factor to cope with the operational and environmental demands placed on the solar cabling.

Installers will test their system design and determine whether there is a need for using an 8 AWG or 6 AWG, but this is rarely needed.

See also: How to install solar panels (Detailed Step-By-Step Guide)

Are All Solar 10 AWG Wire Good Enough?

The wire dimensions may be identical, but not all 10 AWG wires are identical. Do not be lured into buying cheap solar cable online. The lower-cost versions of 10 AWG are not made of pure Copper.

Suppliers will use aluminum or copper-coated aluminum wire and sell this as a lower-cost alternative. The wire’s insulation is another area where low-cost products fall short.

The outer coating must resist UV, ozone, moisture, temperature, and rodent resistance. Another layer of insulation binds the metal strands of wire tightly together and assists with cable flexibility.

Solid Wire Vs. Copper Wire

Solid core wire is less flexible than stranded copper wire and thinner. Stranded copper wire has higher amperage when compared to solid core copper wire.

Do not be seduced by low-cost solar cable. The total cost of cabling will be small compared to the cost of the other solar system components.

Look for solar cabling with UL markings and other specifications on the outer sleeve with (UL) 10 AWG RPVU. The wire is available in red and black on 500ft spools.

10 AWG Features

- Underwriters Laboratory Accredited

- Rated 90°C wet and dry

- Rated for direct burial

- Stranded copper, flexible, 19 strands

- XLPE insulation

- Deformation-resistant at high temperatures

- Excellent moisture resistance exceeds UL 44

- Stable electrical properties over a broad temperature range

- Excellent resistance to crush and compression cuts

- Resistant to most oils and chemicals

- UV/sunlight resistant

- Meets cold bend and cold impact tests at -40°C

You can purchase UL-rated cables from the most reputable big box stores in the United States and Canada. If your solar system installer is procuring all the components for the system, they will most likely get better pricing as they are buying this type of cable in bulk.

Long Lasting Solar Panels and Components

Payback time on home solar systems has fallen below five years and continues to decrease as grid power costs increase, and PV technology becomes more widely used.

The cost of wiring with the best quality cables of the specified gauge will not be the major cost contributor to your installation.

Your solar installation has to last thirty years in the elements and delivers reliable performance for the full lifespan. The cables and connectors are the most vulnerable component to the onslaught of the sun, extreme temperatures, rain, and rodents attack.

The Best Wire For Solar Panels

Invest in the best quality 10 AWG Copper photovoltaic cabling for your installation to ensure maximum performance from your solar system.

The cost of a solar system has significantly reduced and now yields the most cost-efficient power generation available.

Work with reputable solar system designers and installers to ensure that your system is optimally sized, installed, and maintained to give you the best return on investment possible.

You will enjoy free power for twenty to twenty-five years if you get the installation done right the first time with the capacity to expand as your needs grow.

References: